The Rising Asphalt Economy: Why Recycling Bitumen and Asphalt is Important

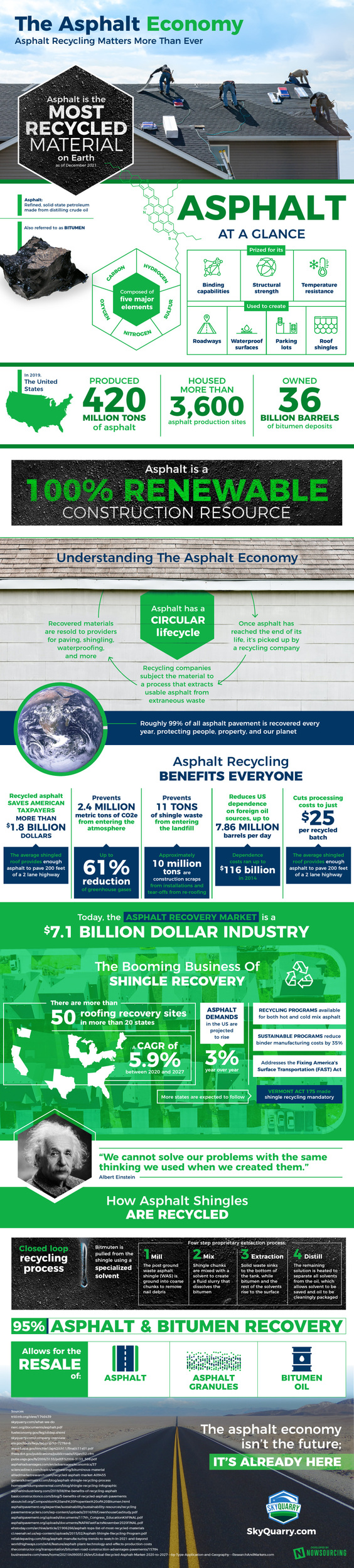

Asphalt is one of the most recycled materials on the planet at the moment. It is a mixture of aggregates, filler, and binder used for construction. Asphalt (also known as blacktop) is mostly used for keeping roads, sidewalks, bicycle lanes, railway tracks, airport runways, and parking areas as well as sport areas intact.

Aggregates that are used for asphalt mixtures can include small pieces of gravel, rock, sand, or slags and make up 95% of the asphalt mix. These days construction and demolition debris along with specific by-products are also included in aggregates, which contributes to asphalt’s sustainability.

A binder is used to keep all the aggregates together in one mixture. Bitumen is the most commonly used binder and is the other 5% of the asphalt mix. Bitumen is a black or thick, dark binder and usually consists of polycyclic hydrocarbons (a byproduct of petroleum). Bio-based binders focused on reducing the impact of bitumen on the environment are currently under development.

In terms of the elements, asphalt is composed of nitrogen, carbon, hydrogen, sulfur, and oxygen with very small particles of iron, nickel, and vanadium. An asphalt pavement is typically made of several different layers above the formation level, which includes materials kept together with bitumen. The first layer is referred to as the surface course while the second and lower layers are known as the binder and base courses respectively. This structure allows the pavement to distribute the weight of the traffic on the top-most layer before it reaches the formation level.

Different types of asphalt mixes with various levels of stiffness, resistance, and flexural strength are made and categorized based on the process utilized to combine the aggregate with the bitumen. The hot mix asphalt is created under high temperatures and is the most durable. It is mostly used for highways and runways at airports or other high-traffic areas.

Warm mix asphalt is not made under high temperatures like hot mix asphalt due to the added waxes, zeolites, and emulsions used. This mixture is safer for the environment and consumes less fossil fuels, but the durability is slightly compromised. As a result, it is generally used for low-traffic areas or for repair.

Cold mix asphalt is made without heating the aggregate, which is done by using bitumen emulsified in water. This bitumen breaks easily during the compacting or mixing process. Strength increases when the water evaporates and the asphalt hardens. Cold mix asphalt is most commonly used for roads that have lighter traffic.

The U.S. in 2019 used 420 million tons of asphalt and stored 36 billion barrels of bitumen. Asphalt goes through a circular life cycle that involves going through a process that separates recyclable asphalt from extraneous waste and being resold as asphalt for paving, shingling, and more. In fact, almost all of the asphalt pavement is recovered yearly, which helps our planet.

Asphalt is a resource that is 100% renewable, and recycling it benefits the people around us. For example, recycling asphalt can reduce the amount of CO2e and greenhouse gases entering our atmosphere as well as reduce the use of foreign oil sources. Furthermore, recovering asphalt can save citizens almost $2 billion in taxes.

Shingle recovery continues to grow as a business with more than 50 roofing recovery sites situated in at least 20 states. Demands for asphalt in the U.S. are estimated to rise 3% each year while sustainable programs continue to help lower binder manufacturing costs. Vermont even passed a law that makes shingle recycling mandatory, something we could be seeing expand to other states in the future.

Asphalt shingles are typically recycled through a closed-loop process that first involves asphalt waste being ground into coarser chunks to remove any unnecessary debris before being mixed with a solvent to create a sludge that breaks down the bitumen and separates the heavier waste from the lighter solvents. The rest of the solution is exposed to high temperatures to separate the solvents from the oil, which can both be used afterwards.

The asphalt shingles recycling process recovers about 95% of the asphalt and bitumen. These are then resold and recycled. Asphalt is a very useful and versatile resource that we can sometimes take for granted.

Source: InvestSkyQuarry.com